Design and construction of moulds for thermoplastics

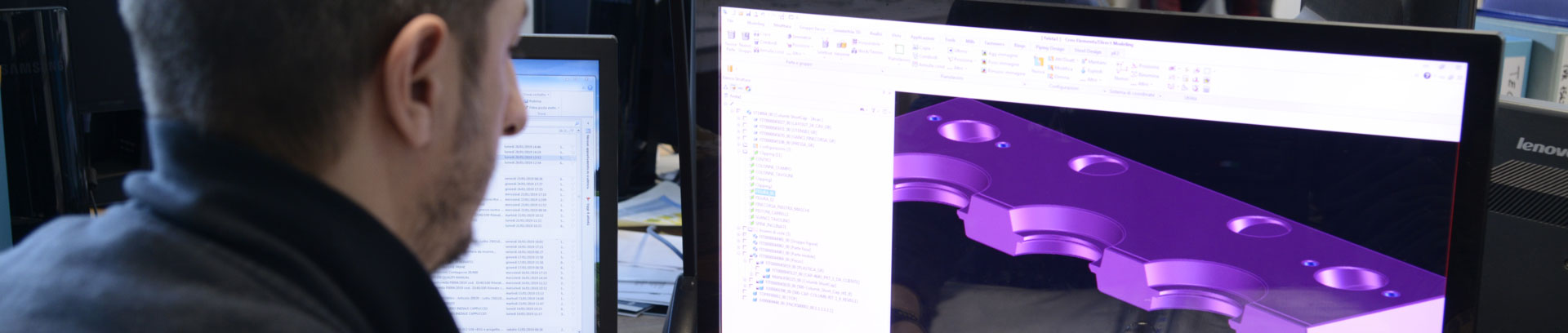

At Abazia, the customer can arrive with an object or a prototype, but also with a 3d print, an idea, a drawing or simple mathematics. From that moment on, we are able to develop the product matrix, accompanying every phase from conception through to industrialization.

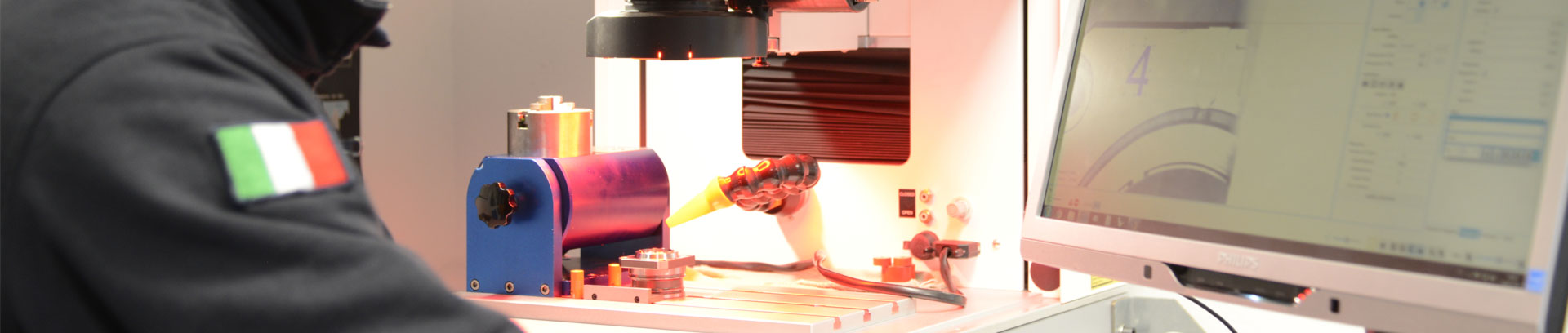

After receiving delivery from the customer, we make a pilot single-cavity mould of the object, examine any defects and seek out the best solutions for improving it. Then we make multi-cavity moulds at high speed, being specialized in producing moulds that achieve millions of strokes with cycles from 4 and up to 10 seconds.

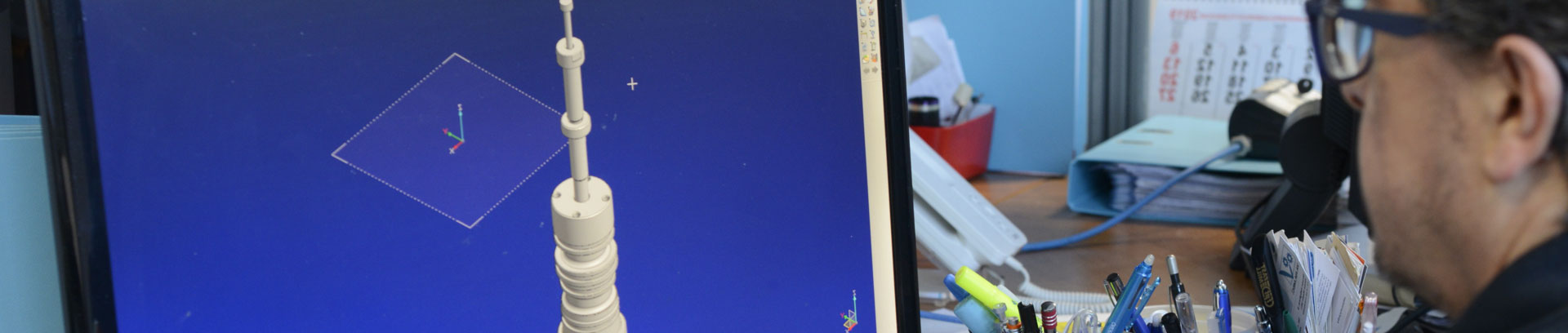

No prototype scares us, not even the most complex. But every idea must be studied together with the customer, because it can often be simplified in order to be successful.